Traditional Textile in Bangladesh specifically hand loom weaving technology is our tradition. Handloom weaving is a cottage based industry spread throughout the country. The sound of the handloom is the music of the rural home inviting fortune to them. In the process of weaving the handloom weaver create a harmony of motion and rhythm.

Historically handloom has got its predominance and heritages in Bangladesh. The tradition of weaving cloth by hand constitutes one of the richest aspects of Bangladesh culture and heritage. The level of artistry and intricacy achieved in handloom fabrics are unparallel and unique. The handloom can meet every need from exquisite fabrics of daily use. The industry has displayed innate resilience to withstand and adopt itself to the changing demand of modern times.

2. Importance of Handlooms in Bangladesh

A manpower of about one million weavers, dyers, hand spinners, embroiderers and allied artisans have been using their creative skills into more than 0.30 million active looms to produce around 620 million meters of fabrics annually. It shares 63% of the total fabric production in the country designed for home consumption, meeting 40% of the local demand for fabrics. Besides, it provides employment opportunities to a million rural people, 50% of which are female. Another half a million people are indirectly engaged in the industry. It contributes more than 10 (ten) billion taka annually to the national exchequer as value addition.

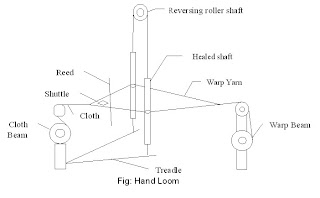

Hand loom:

Hand loom is a machine or device which is made from wood and some portion of iron and used to produce woven fabric. Hand loom running without any electrical motor, its urn by man’s hand and foot combination.

Different parts name of a hand loom as like:

- Reed

- Heald shaft

- Treadle

- Cloth beam

- Shuttle

- Warp beam

- Reversing roller shaft

3.1 Warp thread and pin winding

Warp thread prepared for warp beam produce which place on the loom. Pin wind for use in shuttle. Thread winding into one kind of pin which prepared by hand mechanism by use of hand winding machine. These machines made from wood, iron, thread and bamboo. This machine was called in rural language at “Charki”. These types of machine operate by basically women.

The yarn than is attach with a round cercal then yarn wind into a pin which use as warp beam preparation. Above the picture show that the winding the pin by use of “Charki”. Yarn traverse over two pin at a time by hand and uniformly.

3.2 Warp beam preparation

Wrap beam prepared mechanism is the most important part of weaving. Basically, in our country warp beam is produce according to the fabric structure and design such as Tangail silk saree namely Tangail Muslin, Jamdani saree, silk sarees, Tangail Muslins and Zari, Loggi and Gamcha.

The pin is arranged into a frame according to the weaving structure. The threads are passes through a reed which made from wood. The threads are winding a “dram” (rural language) according specific parameter. The “dram” also made from wood and which is rated by hand up to achieved required diameter.

After winding of threads then it’s unwinding into a beam which also made wood and small portion of iron. The wood beam is place between the two stands which made from bamboo. One kind of handle is place on end of the beam and by this the warp beam is rotated by hand. The “dram” is also rated with the beam and produce warp beam.

1.3 Drafting, Denting and Loom Setting for weaving

1.3 Handloom Weaving Mechanism

The hand weaving mechanism is done simple and operates by weavers hand and foot combination together. It’s a nice art of a weaver’s body movement. The hand loom weaving mechanism or technique is given below:

· Shedding: Divination of warp threads into two parts for insertion of weft threads is called shed and mechanism of shed is called shedding. In hand loom shedding formation by treadle which operate by weaver’s foot and treadle is connected with heald shaft.

· Picking: Insertion of weft threads through the passage created. Picking is done by weaver’s hand.

· Beating: Pushing the inserted weft yarn into the already woven fabric. It’s done by hand, the reed pushed new inserted weft yarn which attached with batten. Top of the batten have a handle which by weavers gives front and back motion of the batten and beating done.

· Taking up: causes rolling of the cloth roller and cloth.

· Left off: causes unrolling of warp from the warp beam.

2. Types of Hand Loom

In Bangladesh there are six variations of handloom are available in the country consisting of Pit loom, Chittaranjan loom, Komor loom, Frame loom, Benarasi/Jamdani, jacquard, dobby, frame and power loom.

3. Weaving product

The vast majority of Bangladeshi handlooms is engaged in weaving cotton and blended fabrics although handloom cloth of silk earned a good reputation. Famous areas for silk weaving are Rajshahi, Tangail and Nobabgonj. Rajshahi produces mainly silk sarees, a special type of cloth weared by the women folk. Tangail produces also silk saree namely Tangail Muslin and Narayangonj produces the famous Jamdani saree, silk sarees Tangail Muslins and famous jamdani. Zari work called brocade is also famous in Mirpur, Dhaka.

Product assortments made of other are saree , lungie, gamsa, grameen check fabrics, printed bed covers, pillow covers, table mats, kitchen and hand towels, apron, curtain and upholstery, furnishing fabrics, bags bandage etc.

| Handloom units and handlooms ( According to Handloom Census 2003) | |

| Items | Number |

| Total Handloom units | 183512 |

| Total number of handlooms | 505556 |

| Total number of operational looms | 313245 |

| Total number of non operational looms | 192311 |

| Type wise number of looms Pit loom | 169700 |

| Frame loom | 29212 |

| Waist loom | 141684 |

| Semi automatic/ Chittaranjan loom | 150407 |

| Others | 2170 |

| Number of Weavers | |

| Total number of weavers | 888115 |

| Total number of male weavers | 472367 |

| Total number of female weavers | 415748 |

| Handloom Factory ( as of May 2008) | |

| Number of Handloom factory registered with the BHB ( Factory is a production unit having more than 20 looms) | 246 |

1. Muslin Textile From Dhaka

The civilisation of the Indus Valley dates back to 3000 BC and it is here, around the towns of Harappa and Mohen-jo-Daro (now both in Pakistan), that remnants of homespun cotton garments, bone needles and wooden spindles have been discovered dating back to that time.

Muslin a brand name of pre-colonial Bengal textile, especially of Dhaka origins. Muslin was manufactured in the city of Dhaka and in some surrounding stations, by local skill with locally produced cotton and attained world-wide fame as the Dhaka Muslin.

The finest sort of Muslin was made of phuti cotton, which was grown in certain localities on the banks of the Brahmaputra and her branches. The other kinds of cotton called bairait and desee were inferior and were produced in different parts of Dhaka and neighbouring areas.

The finest sort of Muslin was called Malmal, sometimes mentioned as Malmal Shahi or Malmal Khas by foreign travellers. It was costly, and the weavers spent a long time, sometimes six months, to make a piece of this sort. It was used by emperors, nawabs etc. Muslins procured for emperors.

2. Business opportunities

8.1 Local Market

Baburhat an inter-district wholesale centre well-known for trading in handloom Textile. Its full name is Shekherchar Baburhat. It is located at Shekherchar in Sadar upazila of Narsingdi district on the bank of the Brahmaputra. Shekherchar there is a small market known as Madhabdirhat or Madhabdi Baburhat. It is located in Araihazar upazila of Narayanganj district.

The cost of producing the simplest form of benarasi sari is more than Tk 2,000 but they have a price ceiling of Tk 2,500 to sell it in the local market, which apparently limits their opportunity to make profit, says Bhola Mer Karim, an owner of a benarasi sari factory.

8.2 Export Market

Many incentives are being provided to the exporters under existing export policy of the Government of Bangladesh. Export policies/incentives applicable to the handloom sector mainly are as follows:

- To encourage the export manufacturing firms exporting at least 80% of their products will be eligible for the following incentives and facilities:

v They will be entitled financial incentives and facilities including Bank credit as 100% export oriented industries. But the taxation facilities allowable to 100% export oriented industries will not be applicable for them.

v These industries will be able to sell 20% of their products in the local market

B. Enhancement of time limit of export credit from 180 days to 270 days.

C. Reduction of bank interest rates: interest on loan for export is fixed at 8%-10%.

D. Opportunity for use of foreign exchange by the exporters. Exporters are given

opportunities to retain 50% of the export earning in their own account in normal cases and 10% of export earning in cases of lower value addition.

Conclusion

The annual demand for weaved fabrics is measured at approximately 168 crore metres and the local handlooms now have the capacity to meet merely 40 per cent of the demand. But now days in our country hand loom industry decrease because increase forgine products such Indian saree. The Handloom Industry has no alternative in the development of rural economy. So we should be increase the use of product of hand loom for developed our rural economy which by increase our economy.

10 Source of Information:______________________________________

1. Bangladesh Hand Loom Board

2. Source of picture:

a. Shekherchar, Baburhat, Narsingdi

b. Lotubdi, Araihazar, Narayanganj

3. Limligth fashion

Publish on 27 February 2010

Page no. 41

4. Banglapedia

this work reminds me of a master degree of anthropology which I have read in Dhacca. Did you by the way have been the master student who made this work? Hope to hear from you olimdevona@gmail.com

ReplyDeleteHello Everybody,

ReplyDeleteMy name is Ahmad Asnul Brunei, I contacted Mr Osman Loan Firm for a business loan amount of $250,000, Then i was told about the step of approving my requested loan amount, after taking the risk again because i was so much desperate of setting up a business to my greatest surprise, the loan amount was credited to my bank account within 24 banking hours without any stress of getting my loan. I was surprise because i was first fall a victim of scam! If you are interested of securing any loan amount & you are located in any country, I'll advise you can contact Mr Osman Loan Firm via email osmanloanserves@gmail.com

LOAN APPLICATION INFORMATION FORM

First name......

Middle name.....

2) Gender:.........

3) Loan Amount Needed:.........

4) Loan Duration:.........

5) Country:.........

6) Home Address:.........

7) Mobile Number:.........

8) Email address..........

9) Monthly Income:.....................

10) Occupation:...........................

11)Which site did you here about us.....................

Thanks and Best Regards.

Derek Email osmanloanserves@gmail.com